Our Services

Non-Destructive Testing (NDT)

non-destructive testing (NDT) systems

Hidden structural weakness can be risky blind spots of infrastructural assets, and quickly turn into silent threats if left undetected. Understanding a structure’s underlying condition is key to preventing failures, ensuring longevity, and protecting investments.

Traditional inspection methods often require breaking or damaging elements, which is disruptive and costly. NVLN Constructions specializes in Non-Destructive Testing (NDT) solutions that assess the health of existing concrete structures without damaging any elements. These advanced diagnostics identify internal flaws, deterioration levels, and corrosion risks, and provide blue-print for data-driven repair and retrofitting decisions. Our NDT services are designed to help you act early, save costs, and ensure public safety.

Our testing systems comply with all relevant national and international codes and standards.

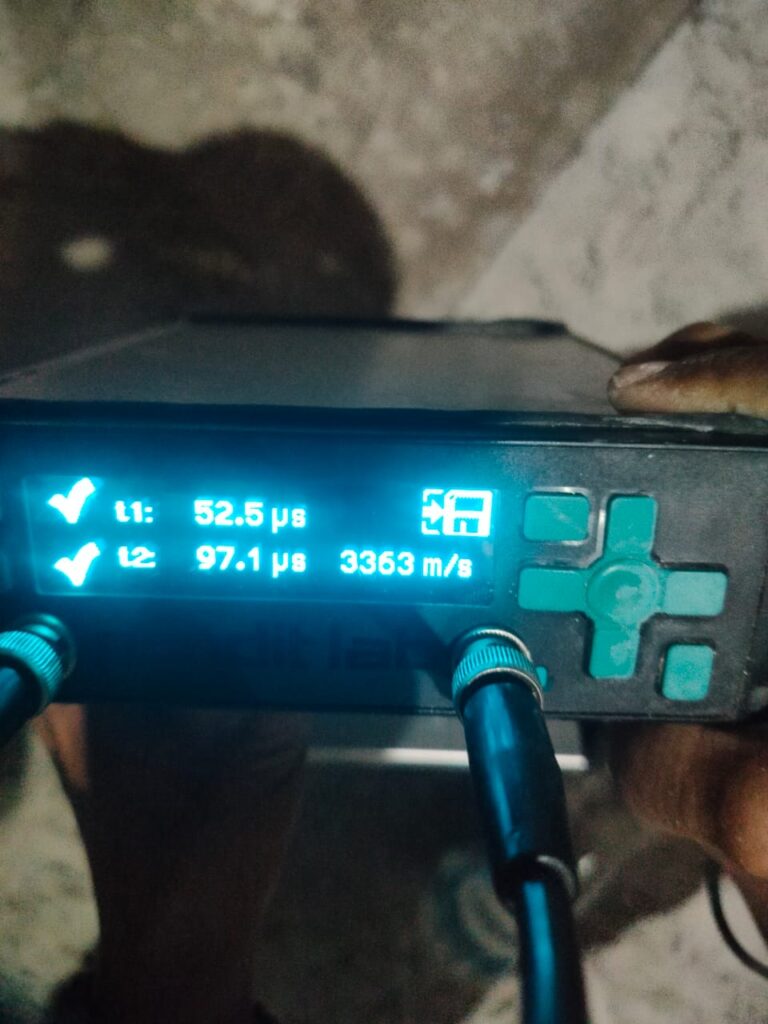

Ultrasonic Pulse Velocity (UPV) Test

UPV test uses high-frequency sound waves to evaluate concrete quality, homogeneity, and detect hidden flaws such as voids, cracks, and honeycombs. In practice, UPV testing is widely applied on RCC structural elements to evaluate structural soundness prior to core extraction, load testing, or strengthening interventions.

Rebound Hammer Test

Rebound Hammer Test is a quick and economical test that estimates compressive strength and uniformity of concrete surfaces. It is ideal for preliminary evaluations and often used to locate weak zones in parking decks and factory floors.

Half-Cell Potential Measurement

Half-Cell Potential is an electrochemical technique for assessing the probability of corrosion activity in embedded reinforcement. By mapping potential differences on the surface, the test identifies zones vulnerable to corrosion in most RCC structures exposed to moisture, chlorides, or aggressive environments.

Carbonation Test

The Carbonation Test measures the depth of carbonation, a process that lowers concrete alkalinity and increases the risk of reinforcement corrosion. This evaluation is crucial for all RCC elements subjected to urban, industrial, or tunnel environments, and supports durability assessment and service-life prediction of structures.

Cover Meter Test

The Cover Meter (Rebar Locator) test uses electromagnetic sensing to locate reinforcement bars and measure concrete cover depth. Adequate cover is essential for durability and corrosion protection, making this test applicable to all types of RCC structures.

Chemical Testing of Concrete

Chemical testing of concrete allows testing powdered concrete samples in labs to determine presence and extent of chloride, sulphate, alkali content, and other chemicals that impact concrete durability. This test is widely used in industrial flooring and coastal projects where aggressive chemicals may be used frequently.

Core Test

Core test includes extracting cylindrical concrete samples using a core drill to analyze compressive strength and microstructure. This test helps in validating structural safety in old or fire-damaged structures prior to repairs or rehabilitation works.

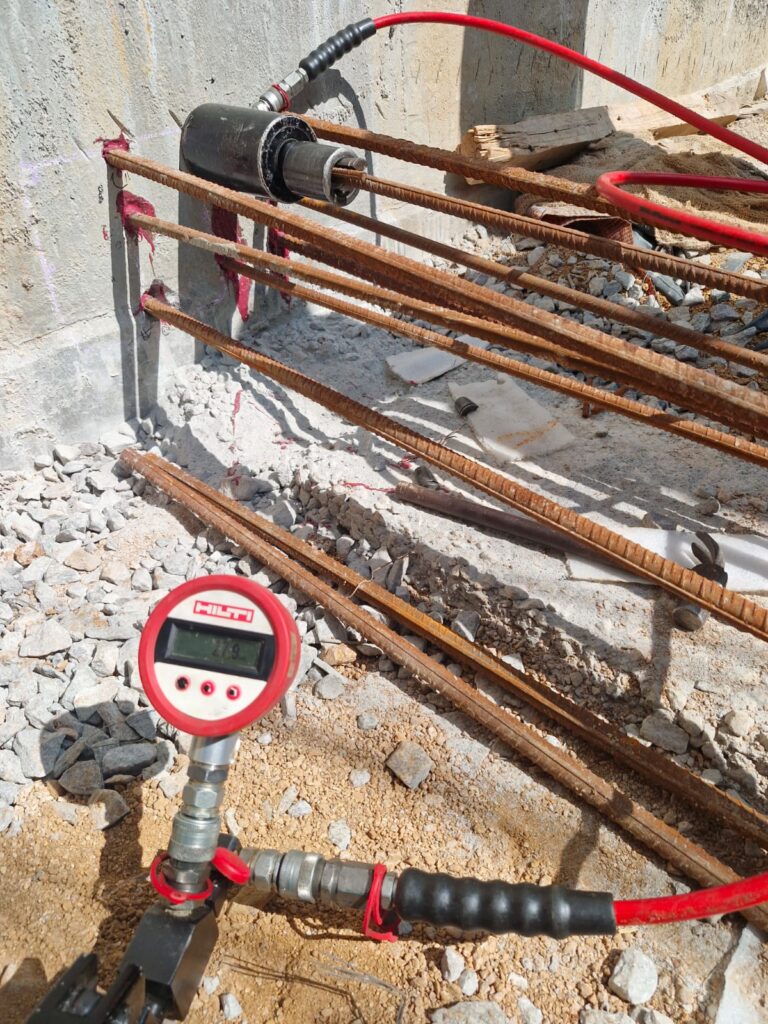

Pull-Out Test

Pull-out is a semi-destructive testing technique that evaluates in-situ strength by pulling out a pre-cast insert embedded in the concrete. This test is often used in verifying load-bearing columns of retrofitted commercial structures to verify in-place strength.

Our comprehensive NDT services help asset owners and stakeholders to make smarter, safer, and cost-effective decisions about their infrastructural assets.